|

5 |

|

|

|

Fisher’s R-80 Tiger Moth Continue

|

|

This picture is a detail of my procedure for pre-bending the rib cap strips. The kit manual states that the cap strips can be fit into the jigs in the dry, straight state, but there is some risk of breakage. I pre-bent the forward third of both top and bottom cap strips by soaking them in water for an hour and then bending the wet wood over a hot pipe. As shown in the picture, the section of pipe is heated by an ordinary propane torch. There is some spring back as the wood cools and dries, but what bend remains is permanent and sufficient to fit easily into the jigs. |

|

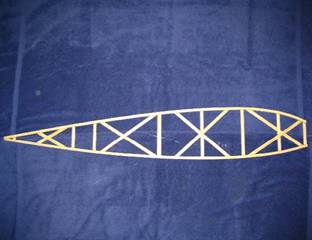

Et voila! One of the finished ribs. All of them are done now and I am in fact building a wing. But that and the spars are stories for another day.

It goes without saying that all of my jigs and specially built tooling are available to any Chapter 180 member who might embark on the same project. It always seems a shame to me that so much effort goes into the construction of such special equipment, only to have it be tossed out after the building of a single airplane. |

|

Rob Brooke

|

|

This picture shows four ribs glued up in the jigs. Four rib jigs are necessary in order to speed production. The T-88 glue must set up for at least 12 hours before a rib can be safely removed from the jig. Having only one jig would mean the production of only one rib a day. |